Advanced deployable reflectors, flexible surfaces, and precision testing for the future of space missions.

Explore our competitive and high performance offering across all deployable reflector and deployable reflector systems domains. From antennas to testing services – we are delivering operational excellence and maintaining industry leadership.

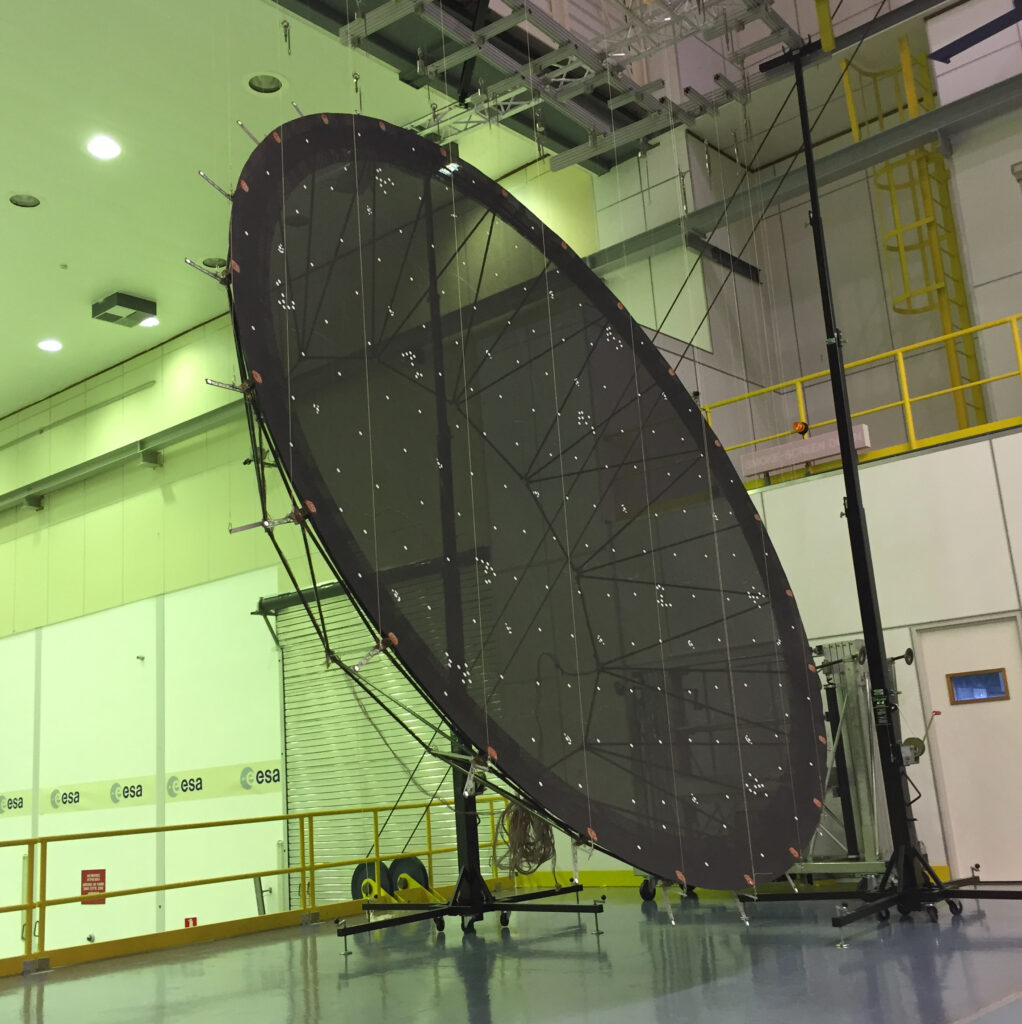

Large deployable reflector systems for high-frequency communication and Earth observation.

Key features:

Ultra-compact, foldable reflectors using LSS’s patented FlexRS® and OriFlex® technology

Benefits:

Use Cases: CubeSat payloads, radar, compact RF systems

Testing of Materials, Components & Structures

Key features:

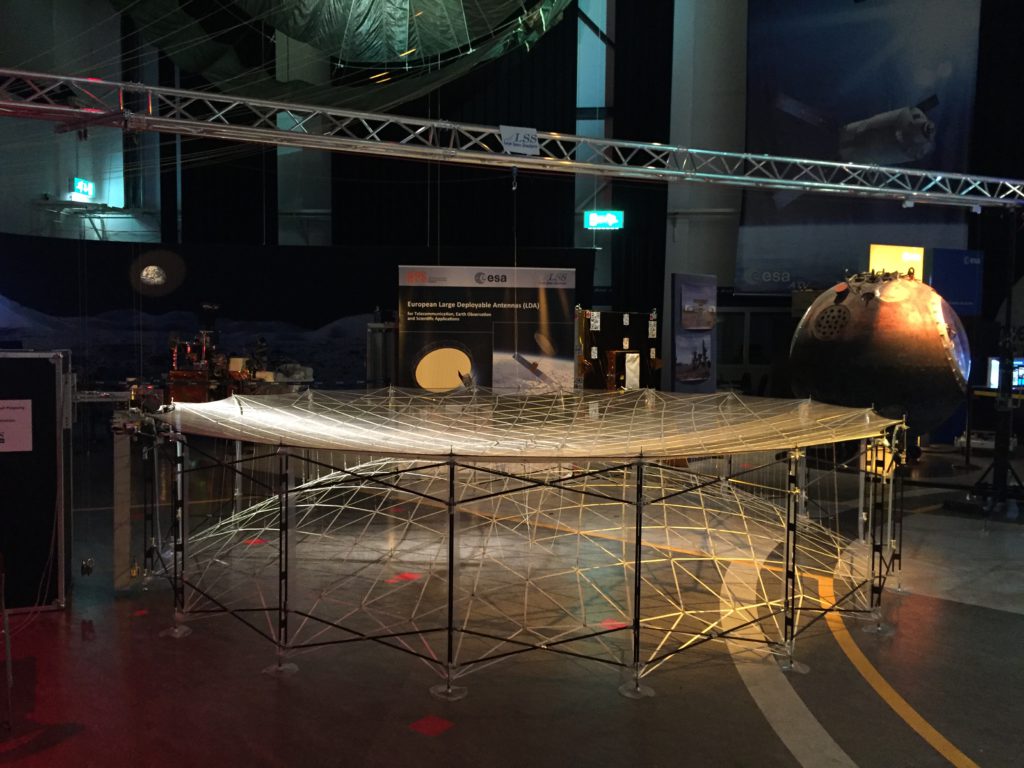

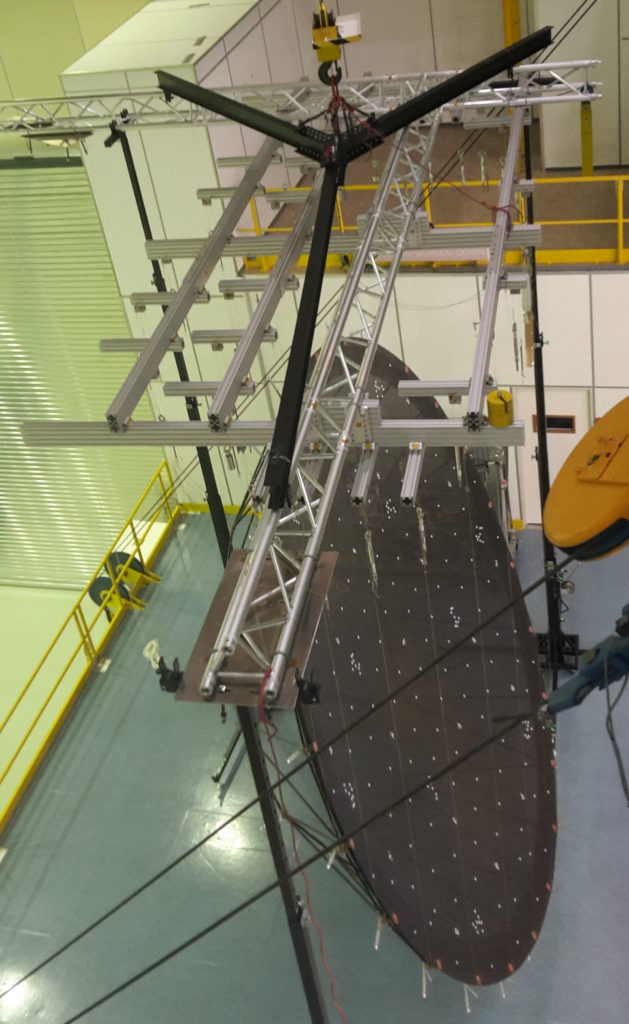

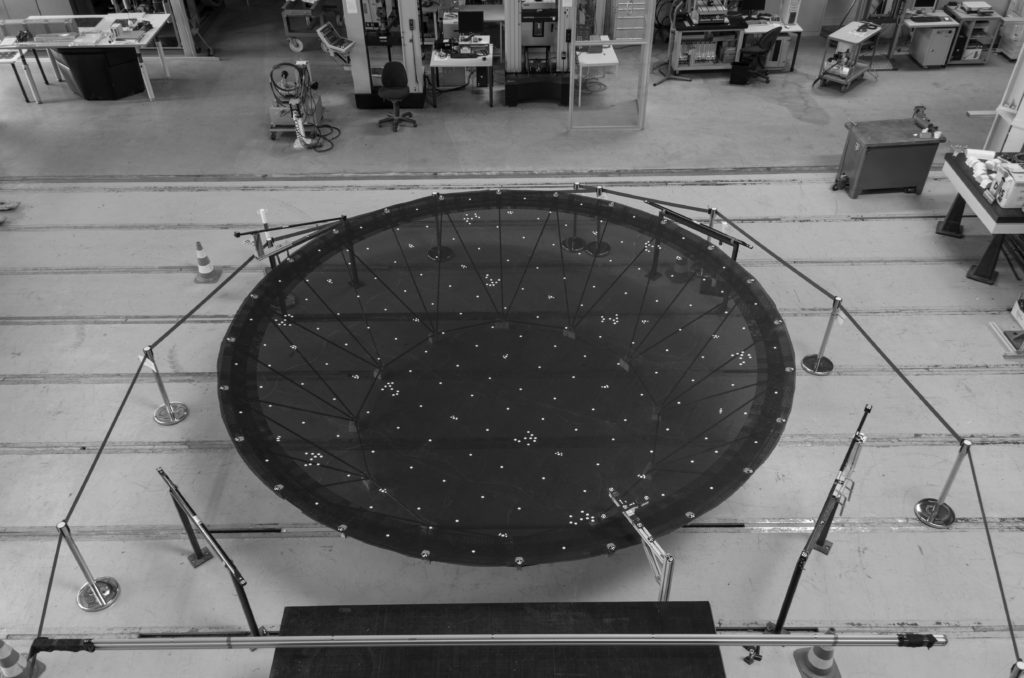

We design and assemble backing structures and mechanical ground support equipment (MGSE) for deployable reflectors.

Benefits:

Use Cases: CubeSat payloads, radar, compact RF systems

Working at Large Space Structures means confronting challenges with innovation, commitment, integrity, passion and team spirit.

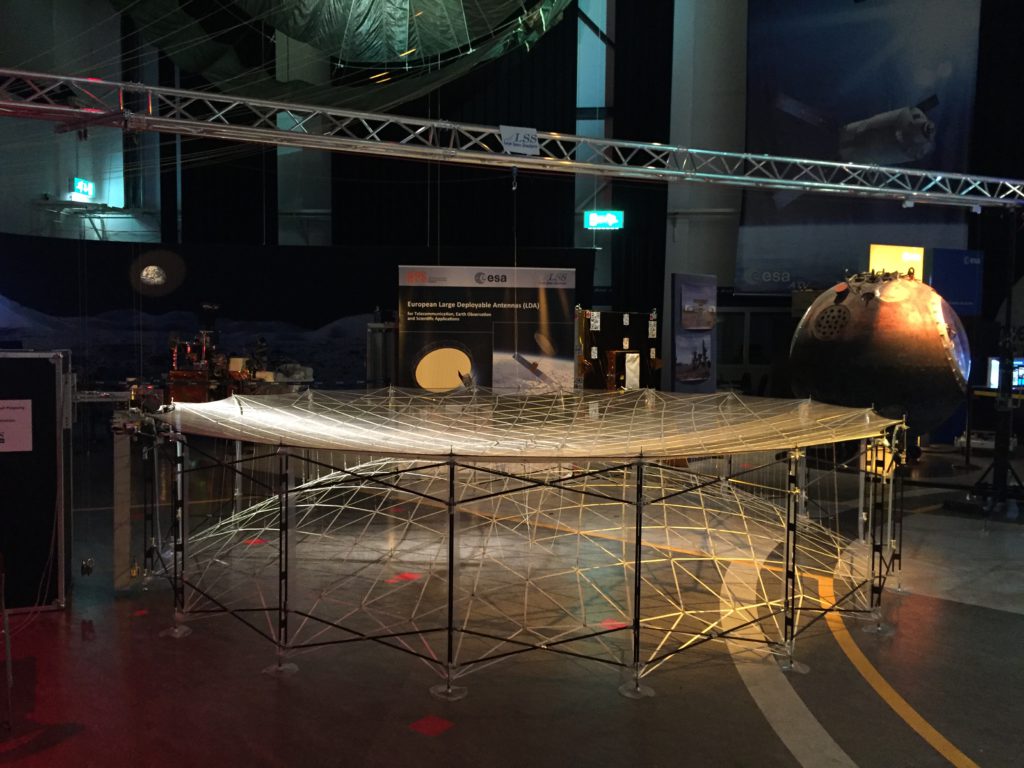

Large Space Structures offers a wide range of high precision reflectors. Varying from Deployable, Shaped Deployable to Reconfigurable Reflectors. Click on the entries below to learn more about our products.

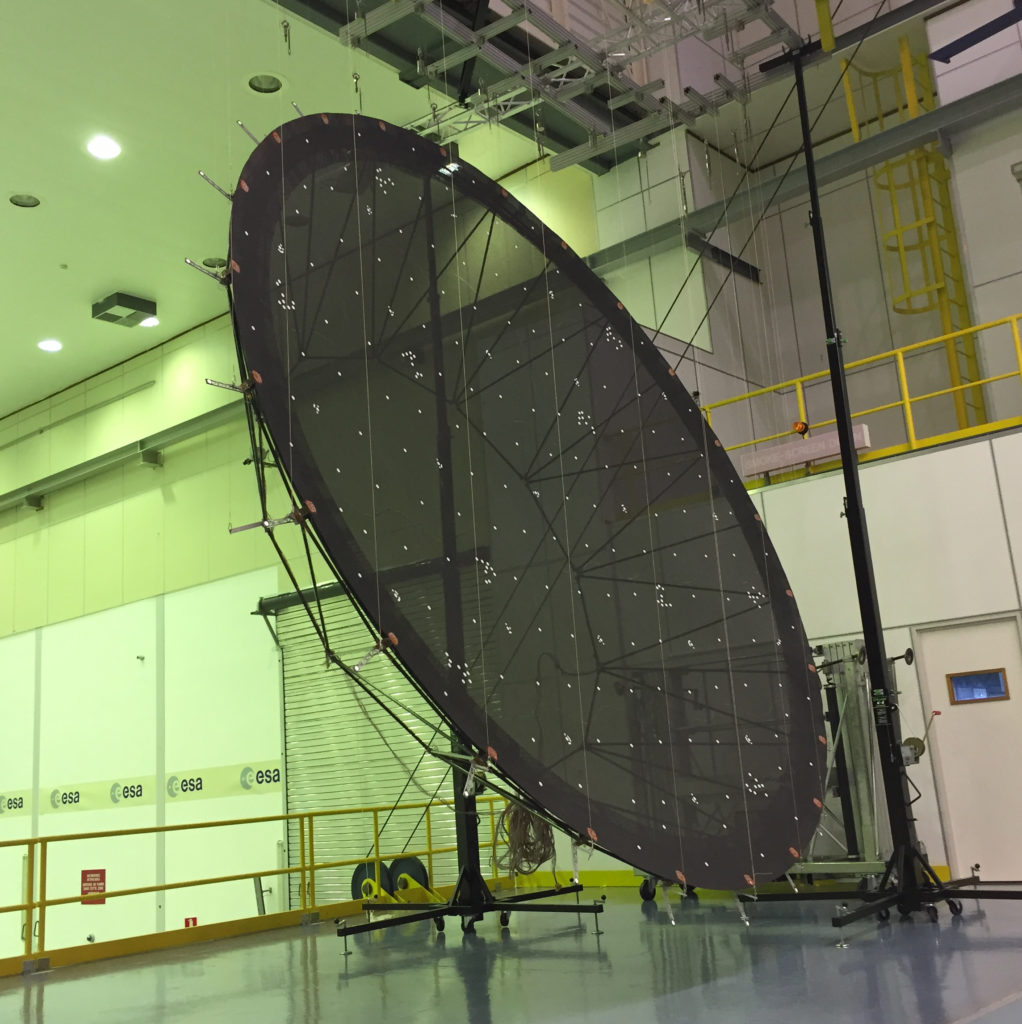

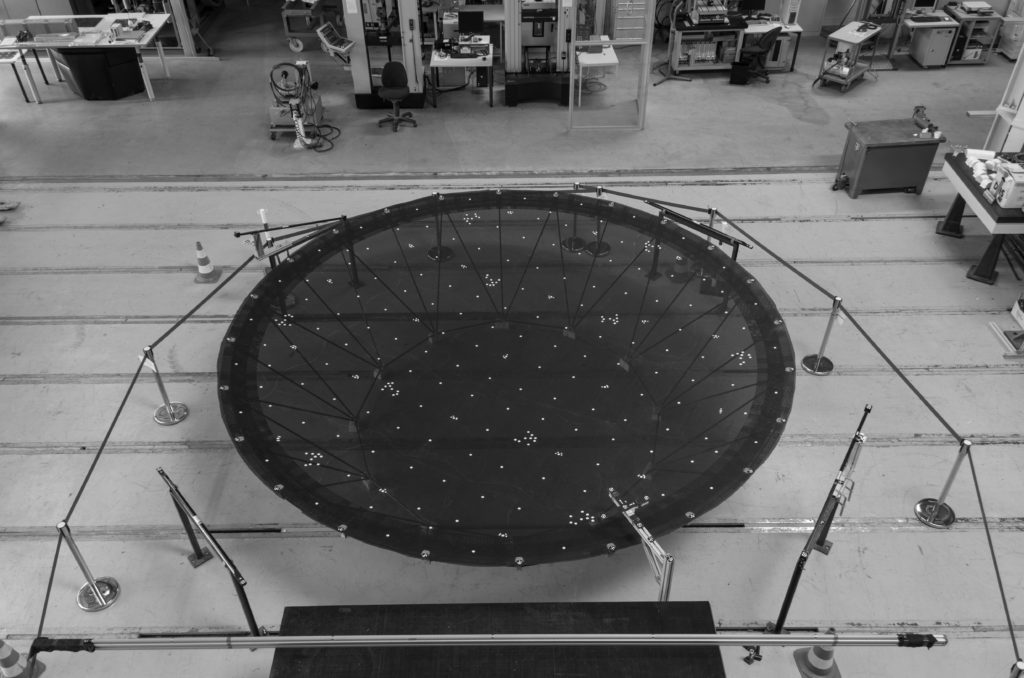

LSS offers deployable antenna reflectors with aperture diameters ranging from 0.5 m to 35 m and above, using different concepts for the deployable backing structure such as umbrella and peripheral ring architectures. The deployable reflectors can be fitted with a broad range of reflecting surface materials / concepts from the FlexRS® technology and can be used for frequencies up to Ka-band, depending on the category. The following categories are available:

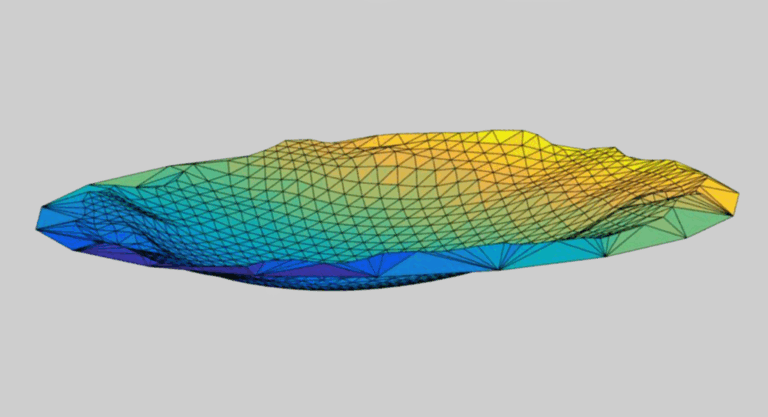

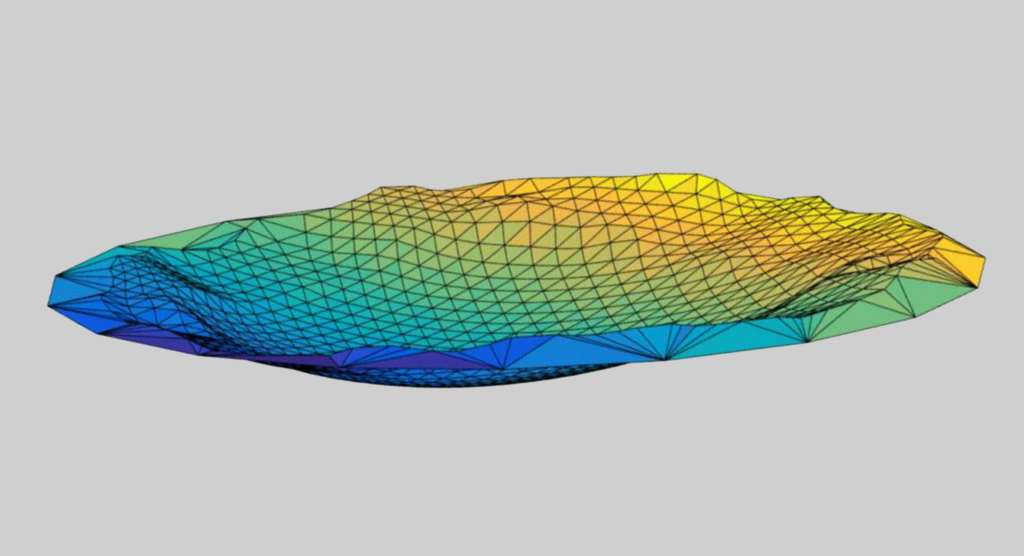

Shaped deployable reflectors are in active development. They combine the advantages of mesh-based deployable reflectors with the capabilities of radiation pattern contouring.

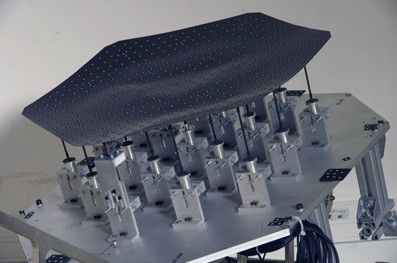

LSS and Thales Alenia Space are working on in-orbit reconfigurable antenna reflectors. LSS supplies the reconfigurable reflecting surface including the interfaces to the actuators. The reconfigurable surface material (FlexRS® Category III) is suitable for frequencies up to Ka-band and can be tailored to provide the desired mechanical properties according to the requirements of the customer.

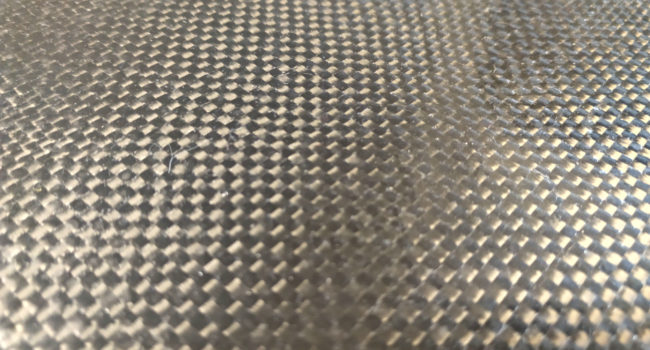

With the FlexRS® product range, Large Space Structures is offering reflecting surfaces in three categories. From very thin and flexile shell structures to pre-stressed metal meshes and flexible shells with increased stiffness the FlexRS® product range offers highes durability for space exploration.

FlexRS® Category I surfaces are very thin and flexible shell structures, which show aspects of membrane as well as shell behavior. They are therefore called Shell Membranes.

Category II surfaces are based on pre-stressed metal meshes, which are typically supported by a cable network or ribs for providing the reflector’s contour.

Category III surfaces are flexible shells with increased stiffness compared to Category I surfaces, while maintaining high deformability and foldability. These surfaces can fully deploy and maintain their shape under microgravity conditions. This enables the creation of deployable reflectors with greatly reduced need for support structures.

Large Space Structures offers you deep experties in designing, planning and manufacturing high precision space products. We are also offering Testing of Materials, Components and Structures.

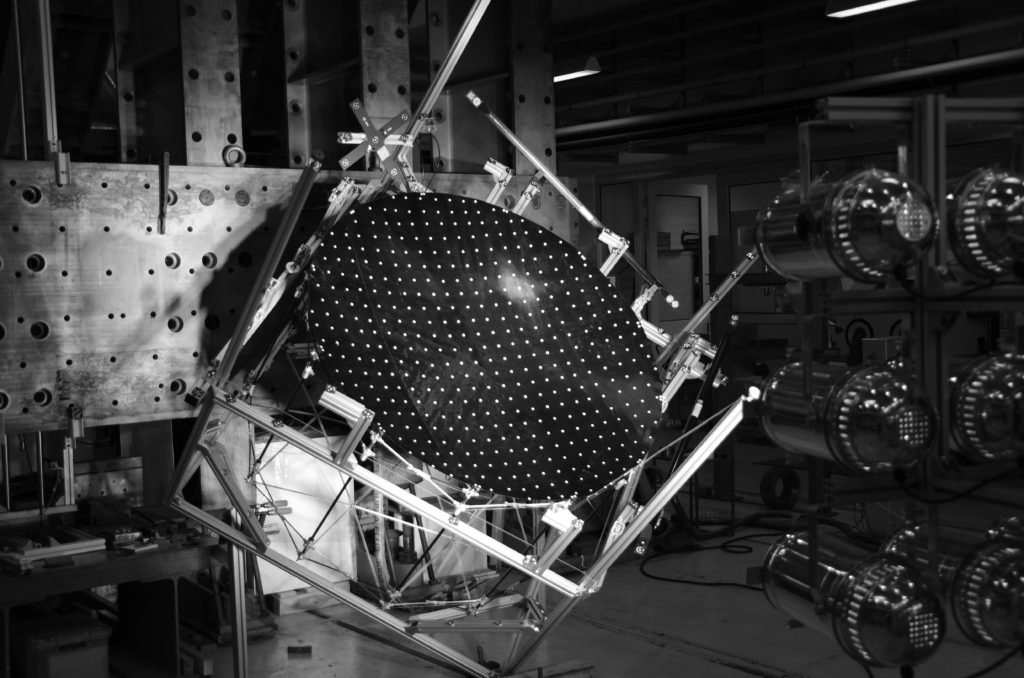

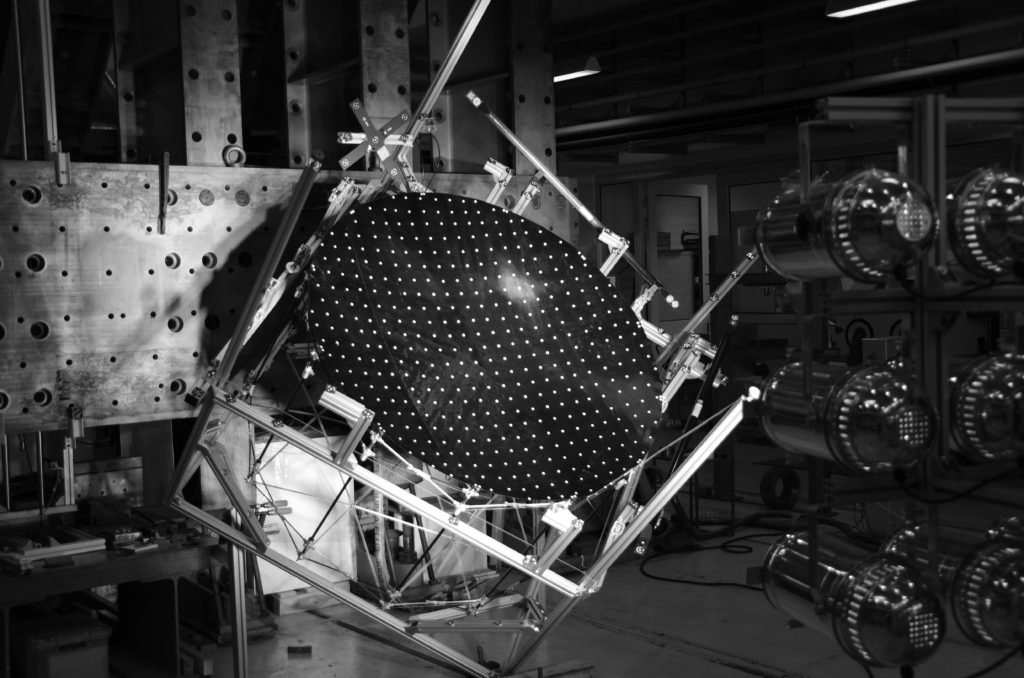

Manufacturing, assembly, integration and testing of breadboards for

Lorem Ipsum

We design and assemble backing structures and mechanical ground support equipment (MGSE) for deployable reflectors.

This typically comprises:

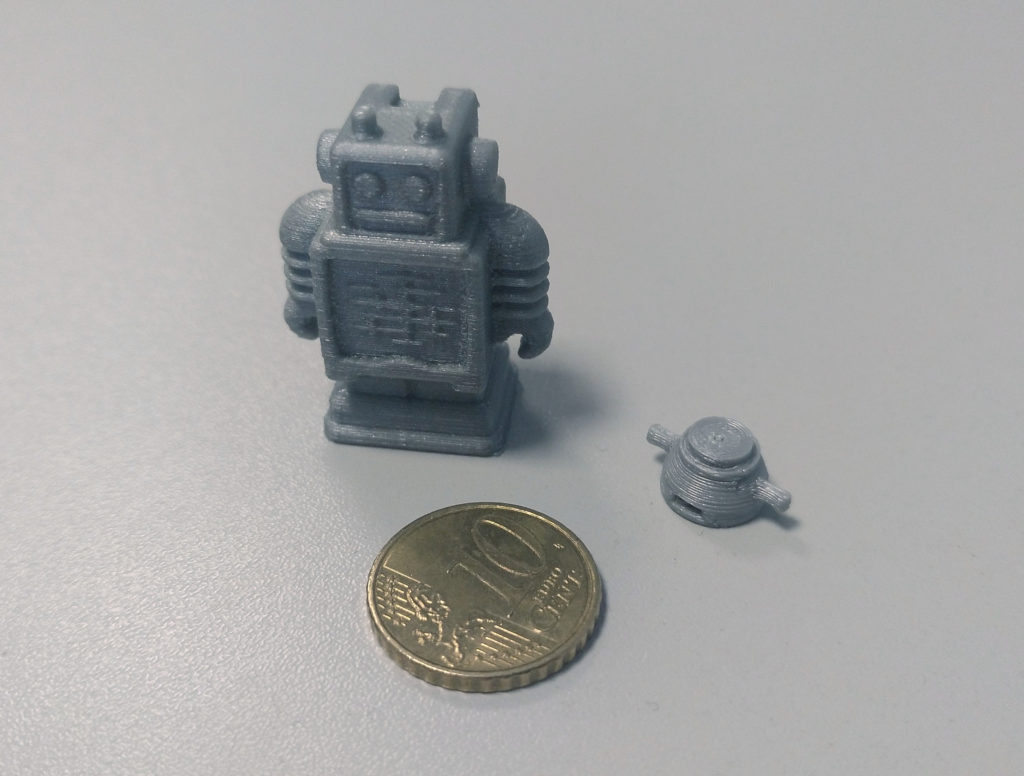

Reusable, non-outgassing contrast based targets for Photogrammetry:

LSS uses an Ultimaker 3 3D printer. The following services are provided to customers: